You love your perfume, but worry the metal sprayer1 is spoiling the scent. Is your expensive fragrance slowly being ruined? It all depends on the quality of the packaging.

Generally, no. Quality sprayers use a plastic pump core, while internal metal parts like springs are stainless steel, which is highly resistant. The outer metal is usually decorative. Reactions are rare unless poor-quality metals or very aggressive fragrance formulas2 are used.

As a manufacturer of glass packaging solutions for over a decade, this is a question my clients and I navigate all the time. The concern is valid, but the answer isn't a simple yes or no. The interaction between perfume and its sprayer depends on two key factors: the specific metals used in the pump and the chemical makeup of the fragrance itself. The beautiful glass bottle is inert, but the sprayer is a complex little machine. Let's break down how these materials work together.

Which Metals Are Safe for Perfume Sprayers?

You see shiny metal sprayer1s and assume they're all safe for perfume. But the wrong metal can cause discoloration and off-odors. Knowing the difference is key.

Stainless steel is the safest for internal parts. Anodized aluminum is good for exteriors. Untreated aluminum and brass are riskier as they can corrode and alter the fragrance, so they often require a protective coating to be used safely.

Not all metals are created equal, especially when they spend years submerged in an alcohol-based solution. In our industry, material selection is everything because it guarantees the product's integrity from the first spray to the last. Some metals are heroes, and others are potential villains if not handled correctly.

A Quick Comparison of Common Metals

The choice of metal is a balance of aesthetics, function, and chemical resistance. Here is how the most common options stack up when in contact with perfume.

| Metal / Structure | Compatibility with Perfume | Typical Use Case | Key Risks & Notes |

|---|---|---|---|

| Stainless Steel | High | Springs, ball bearings, internal parts | The most stable and reliable option. Generally no need for concern as it is highly corrosion-resistant. |

| Anodized Aluminum | Medium–High | Outer casings, decorative collars | The protective anodized layer must be intact. Scratches or exposure to strong acids can lead to corrosion. |

| Brass / Copper Alloy | Low–Medium | Vintage-style caps, decorative parts | Prone to tarnishing and developing a green patina. Should be coated or plated to avoid direct contact with perfume. |

| Electroplated Metal | Medium–High | Most "metal-look" sprayers | Compatibility depends entirely on the quality of the plating and inner plastic components that shield the base metal. |

For everyday use, a pump made with a stainless steel3 spring and a high-quality anodized aluminum4 exterior is the gold standard for protecting your fragrance.

What Perfume Ingredients Cause a Reaction?

You think perfume is just harmless oils and alcohol. But certain ingredients can actively corrode metal, ruining both the sprayer and the scent. Identifying them is the first step.

The main culprits are acidic ingredients5 (like citric acid), sulfur compounds (which tarnish metals), and highly reactive molecules like certain aldehydes. These are more likely to cause issues in water-based formulas or with lower-quality metals.

The fragrance itself can be the aggressor. While most fragrance molecules are perfectly stable, a few specific types of ingredients are known to be reactive with metals. A good formulator considers this and works with packaging experts like us to select a pump system that can handle the formula.

The Troublemakers in Your Fragrance

The risk of corrosion increases significantly when these types of ingredients are present, especially in water-based scents like body mists.

-

Acidic & Polar Ingredients: Some perfumes contain organic acids, like citric acid, to adjust the pH. In the presence of water, these acids can accelerate the breakdown of metals like aluminum and brass. Fragrance ingredients with carboxyl groups (found in some resins) can also increase acidity and corrosion risk.

-

Sulfur and Nitrogen Compounds: Have you ever noticed perfume tarnishing your silver jewelry? That's often due to trace amounts of sulfur-containing ingredients. These compounds have a strong affinity for metals like copper, brass, and silver, causing discoloration and dark spots.

-

Easily Oxidized Molecules: Fragrance molecules like aldehydes (common in citrus and "green" scents) and phenols are prone to oxidation. When this reaction happens near a metal surface, it can disrupt the metal's protective layer and speed up corrosion, leading to rust spots or discoloration on the pump.

Are Luxury Brand Sprayers Really Better?

You pay a premium for luxury perfume, but is the sprayer any different from a cheap one? It feels like you might be overpaying for just a name. The real value is in the hidden details.

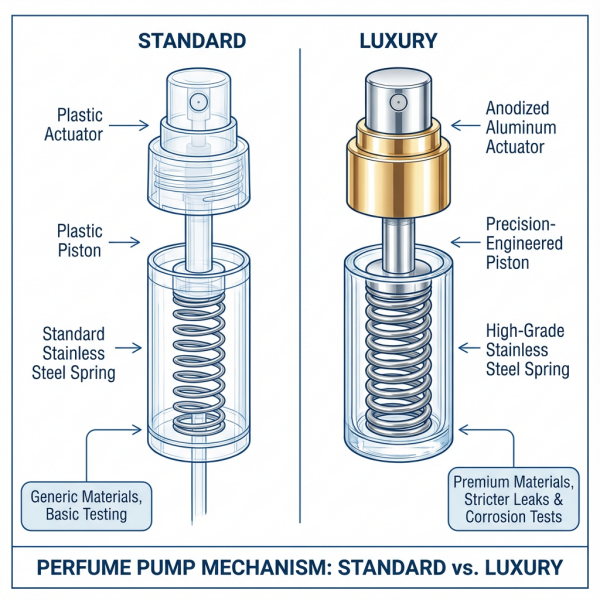

The basic structure—a plastic pump with a stainless steel spring—is often the same. However, luxury brands use higher-grade materials, better anodized aluminum, and perform stricter quality tests for leaks and corrosion. You are paying for precision and reliability.

Having supplied components to brands across the quality spectrum, I can tell you the differences are real, even if they aren't obvious. The fundamental design of a perfume pump is standardized across the industry, but the execution is what separates a high-end product from a standard one.

The Standard Industry Structure

Most perfume sprayers are a clever combination of materials. The core pump engine that does the work is made of inert plastics like PP or POM. The spring and ball bearing inside are typically stainless steel. The visible outer shell or collar is most often aluminum because it's lightweight and easy to decorate. This plastic + stainless steel + aluminum combination is the industry's go-to solution.

Where Luxury Brands Add Value

So if the design is similar, what are you paying for?

- Material Grade and Precision: Luxury brands use higher-grade plastics and stainless steel. Their aluminum components are often thicker and undergo a more robust anodizing process for better protection. The parts are molded with tighter tolerances, ensuring a smoother pump action and better seal.

- Rigorous Testing: High-end brands invest heavily in compatibility testing. They will submerge the pumps in the specific perfume formula for weeks or months at elevated temperatures to ensure there is no corrosion, leakage, or change in the scent. This guarantees long-term performance.

Conclusion

Ultimately, a well-made sprayer won't harm your perfume. Reputable brands use a proven combination of inert plastic, stainless steel, and coated metals to ensure your fragrance remains perfect.

Understanding the effects of metal sprayers can help you choose the right perfume packaging for preserving scent. ↩

Identifying reactive ingredients can help you select perfumes that won't damage sprayers. ↩

Discover why stainless steel is the safest choice for internal parts in perfume sprayers. ↩

Discover the benefits of high-quality anodized aluminum for preserving fragrance integrity. ↩

Learn how acidic ingredients can impact the longevity and quality of your perfume. ↩