You handle wine bottles1 all the time, but when it comes to specifications, the terminology is confusing. This makes it difficult to communicate your exact needs to a manufacturer.

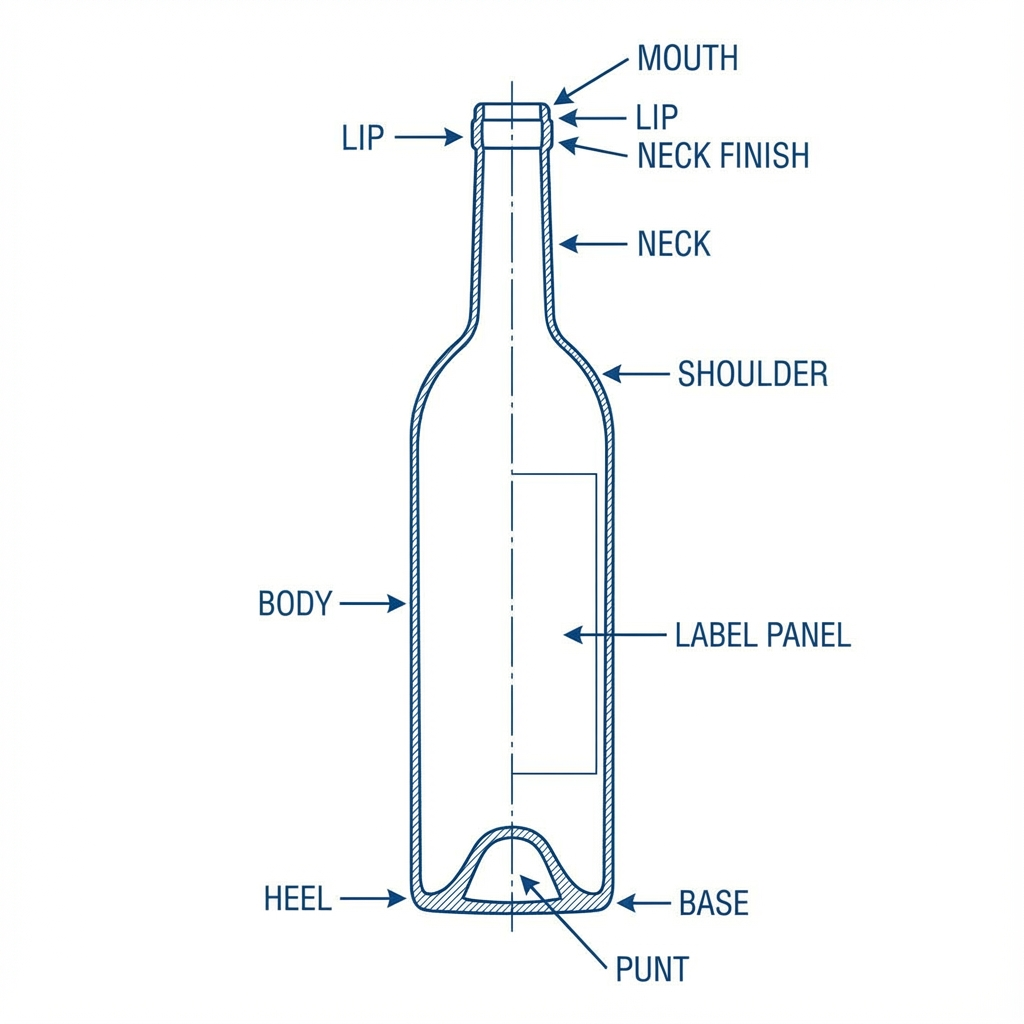

A wine bottle has ten key parts: the Mouth, Lip, Neck Finish, Neck, Shoulder, Body, Label Panel, Heel, Base, and the indented bottom called the Punt. Each component is engineered for preservation, stability, and presentation.

As someone who oversees the production of millions of wine bottles1, I know that every curve and surface has a purpose. Brands often focus only on the overall look, but for us, the magic is in the technical details. A millimeter difference in the neck finish can be the difference between a perfectly preserved wine and a failed batch. Understanding this anatomy isn't just trivia; it's fundamental to quality control and ensuring your wine is presented exactly as you intend.

What Parts Make Up the Top of a Wine Bottle?

The top of the bottle seems simple, but you're worried about getting it wrong. A poor seal can lead to oxidation, spoiling your product and damaging your brand's reputation.

The top section, or "finish," includes the Mouth, Lip, Neck Finish, and Neck. These parts work together to create an airtight seal with a cork or cap and ensure a smooth, controlled pour.

This is the most technically critical zone for us as manufacturers. The entire purpose of the bottle—preservation—relies on the precision here. The Mouth is the opening where the cork goes; its inner diameter, or Bore, must be perfectly uniform to create an airtight seal. The Lip provides the sealing surface for capsules and screw caps. The entire top structure is called the Neck Finish, and we produce it according to strict global standards to ensure it works with automated bottling equipment. Finally, the Neck connects the finish to the rest of the bottle. Its length and shape are not just aesthetic; they control the flow of air and wine during pouring. A tiny flaw in any of these parts can compromise the entire bottle.

What Are the Components of the Bottle's Body?

You think the body of the bottle is just a container for the liquid. But its shape can affect everything from sediment collection to how easily you can apply your label.

The bottle's middle section consists of the Shoulder, the Body, and the Label Panel. The shoulder's slope helps trap sediment, the body provides volume and strength, and the label panel is for branding.

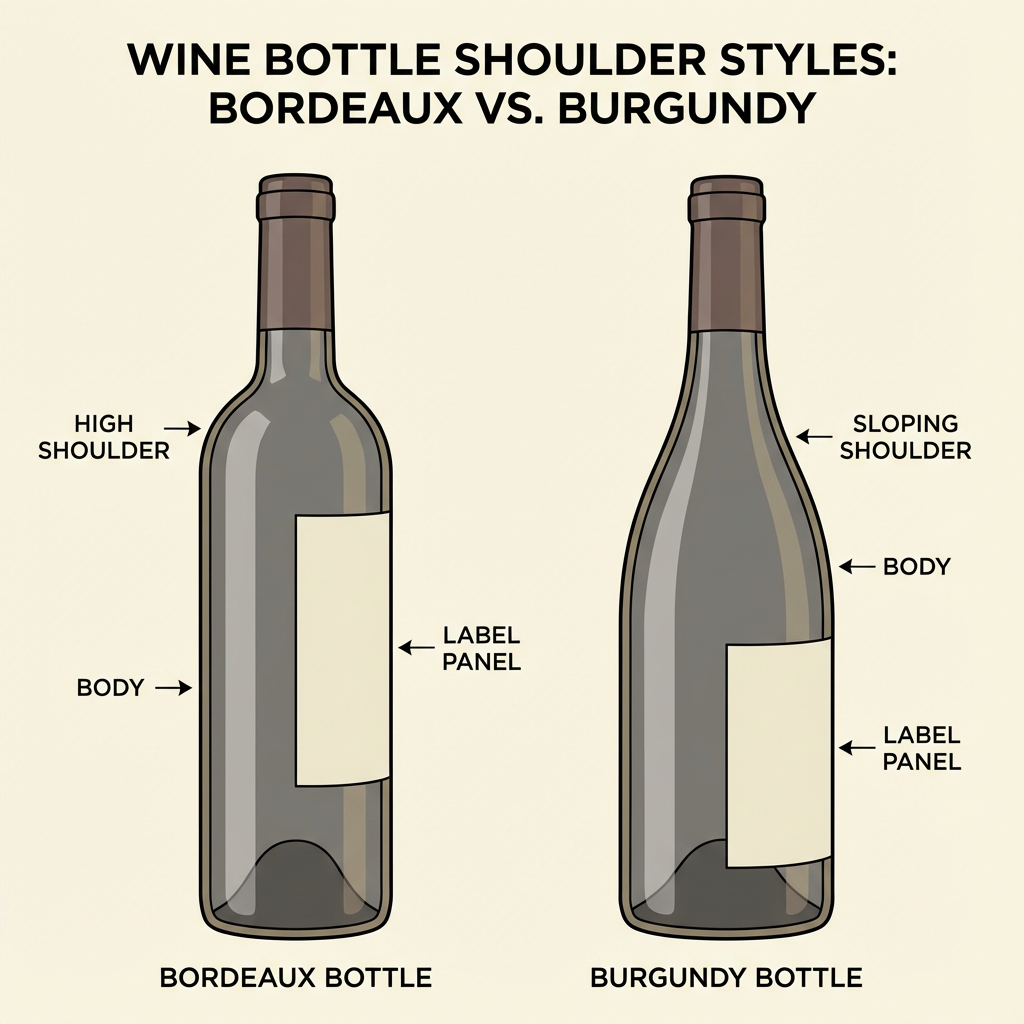

The shape of the bottle's body tells a story. The Shoulder is a key identifier. When a client requests a "Bordeaux bottle," they mean one with high, sharp shoulders, which are excellent for trapping sediment during decanting. A "Burgundy bottle" has gentle, sloping shoulders for wines with less sediment. The main Body is the workhorse, engineered to hold the wine and withstand pressure. For us, a critical quality point is the Label Panel. We have to ensure this area is perfectly smooth and cylindrical. Any imperfection can cause labels to wrinkle or peel on an automated bottling line, which is a major headache for wineries. Getting this right is crucial for a professional, high-end appearance.

What Is the Purpose of the Bottom and the Punt?

You've noticed the dimple in the bottom of most wine bottles1 and wondered why it's there. You might assume it's just a tradition, but it serves several critical modern functions.

The bottle's bottom includes the Heel and Base for stability, and the indented dimple called the Punt. The punt adds significant structural strength, aids in handling, and helps collect sediment away from the pour.

The punt is one of the most misunderstood parts of a wine bottle. In our factory, it's a critical element of structural engineering. For sparkling wines, a deep Punt is essential to help the bottle withstand high internal pressure. It also makes the bottle easier for automated machinery to grab and maneuver on the production line. Historically, it helped glassblowers form the bottle and provided stability on uneven surfaces. Today, it also serves to collect sediment in aged red wines, keeping it from mixing into the wine as you pour the last glass. The Heel is the curved edge leading to the flat Base, which ensures the bottle stands upright without wobbling.

Quick Reference: Wine Bottle Parts

| Part Name | Alternative Term | Primary Function |

|---|---|---|

| Mouth | Orifice, Bore | Opening for filling and sealing with a cork. |

| Lip | Sealing Surface | Provides a sealing surface for capsules and screw caps. |

| Neck Finish | Finish | The entire top structure that holds the closure. |

| Neck | N/A | Connects the finish to the shoulder and facilitates pouring. |

| Shoulder | N/A | Traps sediment and defines the bottle's style. |

| Body | Barrel | Holds the wine and provides a surface for the label. |

| Label Panel | N/A | The flat area on the body designed for label application. |

| Heel | N/A | The curved transition from the body to the base. |

| Base | N/A | The flat bottom surface that provides stability. |

| Punt | Push-up, Kick-up | Adds strength, aids handling, and collects sediment. |

Conclusion

From the sealing precision of the neck finish to the structural strength of the punt, every part of a wine bottle is engineered for quality, preservation, and presentation.

Explore this link to discover the various types of wine bottles, their unique shapes, and how each design impacts wine preservation and presentation. ↩