You believe all glass is equally safe for food, a common but risky assumption. This blind spot could lead to product recalls, failed compliance in key markets, and damage to your brand's reputation.

No, not all glass is equally food-safe. The safety of a glass container depends on its chemical composition (Type I, II, or III) and its resistance to heat and acidic contents. Using the wrong type can compromise your product's integrity.

In my 10+ years of manufacturing glass for global brands, this is one of the first and most critical conversations I have with a new client. They’ll have a great product—a special sauce, a premium beverage—but haven't considered if the bottle itself can handle it. The assumption that "glass is just glass" is a dangerous one. Getting this right is the foundation of a safe, successful product launch, and it's my job to guide you through these crucial details from the very beginning.

What Are the Main Types of Food-Grade Glass?

You see different glass containers but don't understand the real difference. This lack of knowledge makes it hard to choose the right, compliant packaging, putting your product and business at risk.

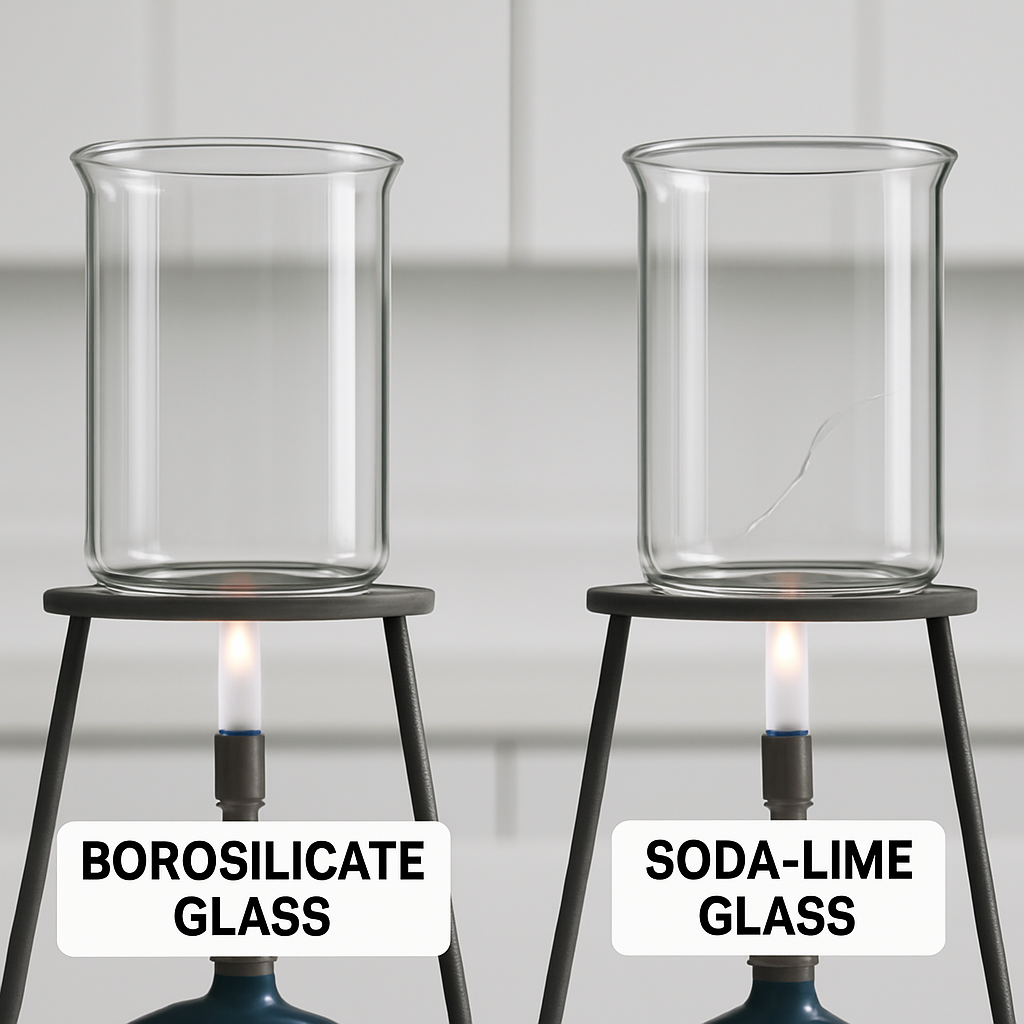

Food-grade glass is mainly classified into three types by regulators like the FDA: Type I (Borosilicate1), Type II (Treated Soda-Lime), and Type III (Soda-Lime). Each offers different levels of chemical and heat resistance for specific applications.

Understanding these three pillars is everything for an importer. It’s the language of safety and compliance. When we start a project, we don't just talk about shape and size; we match the glass type to the product's needs. For a brand owner, knowing this isn't just technical trivia—it's how you protect your investment. Choosing the wrong type isn't a minor mistake; it can lead to leached chemicals or breakage during production, problems that are entirely avoidable with the right expertise.

Type I: Borosilicate Glass (The Premium Choice)

This is the champion of glass packaging. Made with boron oxide, it’s incredibly resistant to thermal shock. This makes it the only choice for products requiring high-temperature sterilization (retorting), like baby food or premium sauces. Its chemical inertness is the best you can get, so it won't react with even highly acidic or alkaline contents. It's the go-to for pharmaceuticals and high-end food products where purity is paramount.

Type III: Soda-Lime Glass (The Industry Standard)

This is the workhorse of the glass industry and what you see most often on store shelves. Made from silica, soda, and lime, it's cost-effective and perfect for a huge range of products like jams, pickles, beer, and wine. It’s highly recyclable and perfectly safe for general use. For most standard food and beverage items that don't need extreme heat processing, Type III soda-lime is the ideal balance of quality, safety, and cost-efficiency.

Type II: Treated Soda-Lime Glass

This is a specialist glass. It's essentially Type III soda-lime glass that has its inner surface treated to increase chemical resistance. This makes it a good middle-ground option for moderately acidic products where Type III might not be enough, but the cost of Type I isn't justified. It's often used for infusion bottles and other specific liquid solutions.

Which Glass Is Right For Your Product?

You're trying to choose between different glass types but are worried about making a costly mistake. Selecting a glass that can't handle your production process or product formula could lead to disaster.

For high-heat processes or very sensitive contents, choose Type I Borosilicate1. For most standard food and beverages like jams or wine, the cost-effective and reliable Type III Soda-Lime is the best choice.

I always walk my clients through a simple decision-making process based on two questions: "What is your product?" and "How will you process it?" If you're hot-filling your sauce or using a retort process for sterilization, the conversation immediately turns to Type I Borosilicate1. Its ability to handle rapid temperature changes without cracking is non-negotiable for these applications. We manufacture borosilicate containers precisely for these high-stress environments. On the other hand, if you're packaging a jam, honey, or wine at ambient temperatures, the robust and economical Type III Soda-Lime glass from our extensive inventory of over 5,000 designs is the perfect fit. It provides all the safety and quality you need without the added expense of high thermal resistance.

| Feature | Type I (Borosilicate) | Type III (Soda-Lime) |

|---|---|---|

| Heat Resistance | Highest (Essential for retorting) | Low |

| Chemical Purity | Highest (Best for sensitive products) | Excellent (Great for general use) |

| Cost | Highest | Lowest |

| Best For | Baby food, premium sauces, pharmaceuticals. | Jams, pickles, honey, beer, wine, soft drinks. |

Is There Any Glass You Should Absolutely Avoid?

You see beautiful, heavy crystal decanters and might think they signal ultimate quality. You might even consider them for a premium product line, assuming that heavier and prettier means safer and better.

Yes. You must avoid lead crystal glass for any commercial food or beverage packaging. The lead that gives the glass its brilliance can leach into the contents, especially if they are acidic, posing a serious health risk.

This is a point I cannot stress enough. Lead crystal is for decorative purposes or short-term serving only. It is never, under any circumstances, suitable for commercial packaging. The risk of lead, a potent neurotoxin, leaching into your product over time is real and can lead to catastrophic health issues and legal liabilities. I've had to steer clients away from this idea in the past. They are drawn to the sparkle and heft, but as a responsible manufacturer, it's my duty to ensure the packaging is unequivocally safe. Your brand's reputation is built on trust, and using lead crystal for storage would shatter that trust completely. Stick to certified Type I or Type III glass from a trusted supplier. It’s the only way to guarantee safety and compliance.

Conclusion

Glass is the safest packaging, but only when you match the correct type to your product. Partnering with an expert manufacturer ensures you make the right, compliant choice every time.

Discover why Borosilicate glass is favored for high-temperature applications and its chemical inertness. ↩