Is glass a rock? Many people are surprised when they hear that glass is made of rock.

As someone who has been engaged in the production and sales of glass bottles for many years, I can tell you that quartzite is not usually used as the main raw material for making glass.

Although quartzite is primarily composed of quartz, a key component of glass, the primary raw material used in glass production is silica sand(SiO2). Silica sand(SiO2) is more commonly used because its silica is highly pure and readily available in large quantities. However, quartzite can be crushed and processed to extract silica sand, which is then used in glass manufacturing.

In this article we will explore the main processes involved in glass bottle production.

1.Batching and Melting

Raw materials such as silica sand, soda ash, limestone, and cullet (recycled glass) are mixed together in precise proportions.

The batch materials are fed into a furnace where they are heated to high temperatures (over 1500°C) until they melt into a homogeneous liquid known as molten glass.

2.Forming

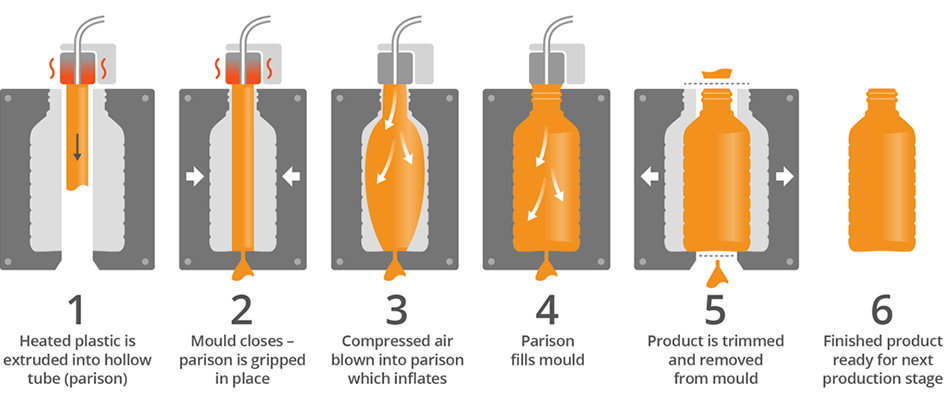

There are several methods for forming glass bottles:

3.Annealing

Once formed, the bottles are gradually cooled in a temperature-controlled annealing lehr (oven) to relieve internal stresses and strengthen the glass.

4. Annealing

Once formed, the bottles are gradually cooled in a temperature-controlled annealing lehr (oven) to relieve internal stresses and strengthen the glass.

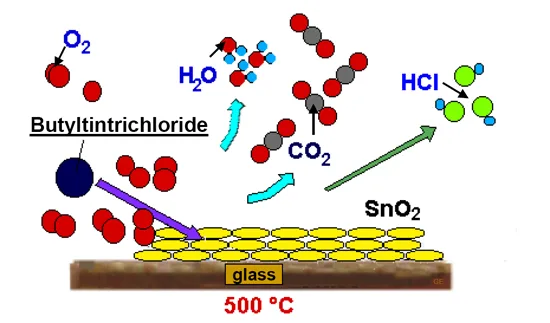

5.Surface treatment

Bottles may undergo additional processes like coating, labeling, or decorating to enhance their appearance or functionality.

6. Inspection and packaging

After surface treatment, bottles are inspected for defects such as cracks, bubbles, or imperfections. Then they are packaged and prepared for shipment.

Crafting glass blends science and art, starting with high-quality silica sand, soda ash, and limestone. These ingredients are melted into molten glass in a furnace. Skilled artisans shape the glass into various forms, from bottles to windows, before it cools and hardens. Tradition and innovation combine to ensure each piece meets the highest standards of craftsmanship, making glassmaking a journey of precision and passion.