Choosing the wrong glass can lead to shattered products and safety recalls. Understanding the difference between high borosilicate and regular glass1 is the key to protecting your brand and customers.

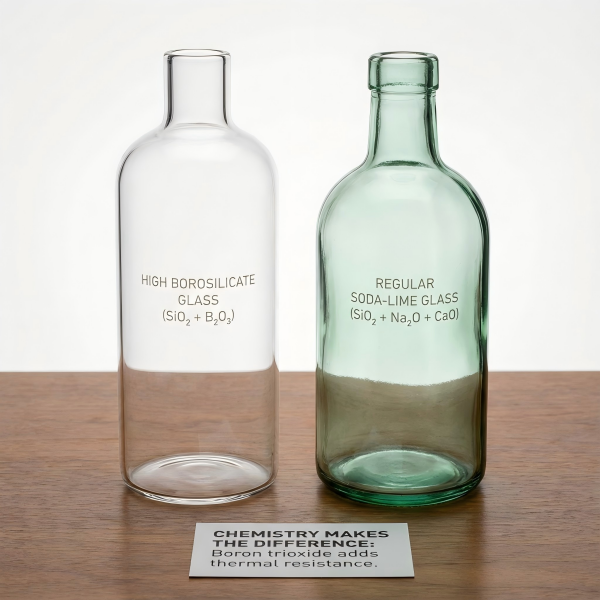

The main difference is chemistry. High borosilicate glass contains boron trioxide, giving it superior resistance to thermal shock (sudden temperature changes). Regular soda-lime glass2 lacks boron, making it likely to crack when exposed to extreme heat or cold.

As someone who helps brands source glass packaging3 every day, I've seen firsthand how critical the right material choice is. It’s about more than just looks; it's about safety, durability, and how your product is perceived in a competitive global market. A lot of people think "glass is just glass," but that simple assumption can lead to costly mistakes. In this guide, I'll break down everything you need to know to make the smart choice for your product, whether it’s for high-end cookware4, pharmaceutical packaging, or everyday storage jars. Let’s get into the details.

What's the Real Difference in Their Makeup?

At first glance, all clear glass looks the same. But using the wrong type for your product can lead to failure. The secret to performance is hidden in the recipe.

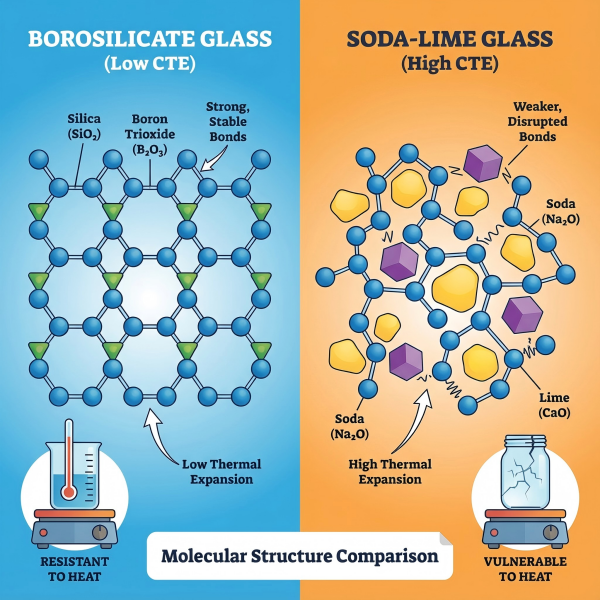

High borosilicate glass is made with silica and boron trioxide, which creates a low coefficient of thermal expansion5 (CTE). Regular soda-lime glass2 is made with silica, soda, and lime, resulting in a much higher CTE, making it vulnerable to heat.

The performance of any glass comes down to its core ingredients. High borosilicate glass is a true specialist. It’s primarily made of silica, but the key is the addition of 8-15% boron trioxide (B₂O₃). This one ingredient is a game-changer, drastically lowering the glass's thermal expansion. On the other hand, regular soda-lime glass2, which makes up about 90% of all glass produced, uses silica, soda (sodium oxide), and lime (calcium oxide). It’s cheap and easy to make, but it expands and contracts much more with temperature changes. This fundamental difference in their "recipe" is why one can go from the freezer to the oven, while the other would simply shatter. It's a classic case of getting what you pay for in terms of performance.

Which Glass Is Stronger Against Heat and Chemicals?

You need glass that can handle hot liquids or long-term storage. But the wrong choice could shatter unexpectedly or react with your product, which is a major safety and quality risk.

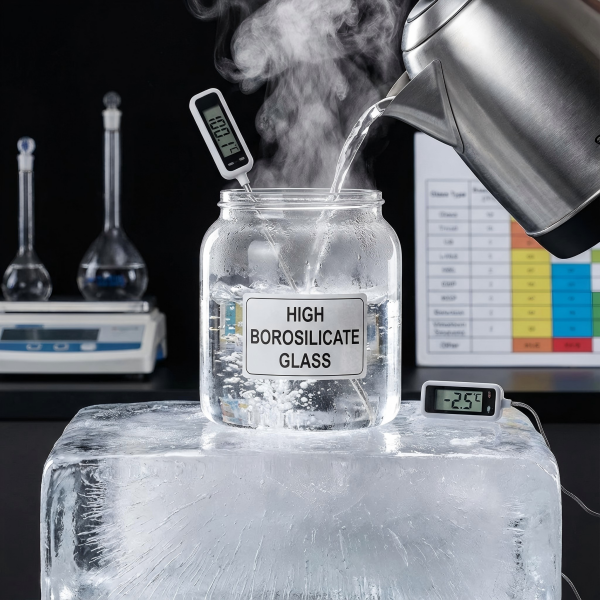

High borosilicate glass is excellent, withstanding temperature changes up to 170°C and resisting chemicals. Regular glass is poor, only handling changes of about 40-50°C, making it unsuitable for thermal stress or sensitive contents.

The most critical test for many of my clients is thermal shock resistance6. Imagine taking a glass container from the fridge and pouring boiling water into it. Regular glass would shatter because the inside expands much faster than the outside, creating immense stress. High borosilicate glass, with its low expansion rate, handles this stress without any issue. This superior performance extends to chemical resistance7, making it perfect for lab equipment or long-term food storage8 where you need to be sure nothing will leach into the product. It's also less dense, so high borosilicate products are noticeably lighter and often have higher clarity, giving them a more premium feel.

| Property | High Borosilicate Glass | Regular Glass (Soda-Lime) | What This Means For You |

|---|---|---|---|

| Thermal Shock | Excellent (handles ~170°C change) | Poor (handles ~45°C change) | Critical for hot-fill or microwave use. |

| Chemical Resistance | Excellent | Good | Essential for pharma or long-term storage. |

| Density | Lower (~2.23 g/cm³) | Higher (~2.5 g/cm³) | Products are lighter and feel premium. |

| Clarity | Higher (More transparent) | Lower (Slight green tint) | Affects how your product is displayed. |

When Should You Use High Borosilicate vs. Regular Glass?

Choosing the right glass for your specific product can be confusing. Making a mismatch can lead to safety issues, product failure, or a perception of low quality from your customers.

Use high borosilicate glass9 for any application needing thermal safety and durability, like cookware, lab vials, or premium cosmetic jars10. Use regular glass1 for standard, cost-effective uses like wine bottles or jars not exposed to extreme temperatures.

I always advise my clients to match the glass to the product's entire lifecycle. High borosilicate is the go-to choice when performance cannot be compromised. This includes:

- Kitchenware: Think oven-safe dishes11, glass teapots, and food containers that go from the freezer to the microwave.

- Pharmaceutical & Lab Use: For beakers and vials that need to be sterilized at high temperatures and hold chemicals without reacting.

- High-End Packaging: For premium cosmetic creams, essential oils, or reusable water bottles where clarity, light weight, and durability justify a higher cost.

Regular glass is the workhorse of the industry for a reason—it’s cost-effective. It is the perfect choice for:

- Standard Food & Beverage: Items like wine and beer bottles, jam jars, and soda bottles where thermal shock isn't a concern.

- General Storage: Basic jars for dry goods in a pantry.

The manufacturing process for high borosilicate requires more energy and specialized equipment, making it more expensive. However, its durability often means a longer lifespan, which is a key factor for reusable products.

Conclusion

Your choice between these two glasses should be guided by your product's needs. High borosilicate is for superior performance and safety, while regular glass1 is for standard, cost-sensitive applications.

Learn about the composition and uses of regular glass in everyday products. ↩

Find out about soda-lime glass, its properties, and common uses in the industry. ↩

Explore the benefits of using glass packaging for various products and sustainability. ↩

Discover the characteristics that make cookware high-end and worth the investment. ↩

Learn how a low coefficient of thermal expansion affects glass performance. ↩

Understand the science behind thermal shock resistance and its importance in glass products. ↩

Discover why chemical resistance is crucial for lab and food storage applications. ↩

Learn about the best glass options for safe and effective long-term food storage. ↩

Explore the advantages of high borosilicate glass for durability and thermal resistance. ↩

Explore why premium cosmetic jars made from high-quality glass enhance product appeal. ↩

Find out what materials are best for oven-safe dishes and their safety features. ↩