Choosing the wrong perfume bottle can ruin your fragrance and brand image. This complex decision involves materials, technology, and costs, where a small mistake can be very expensive.

A luxury perfume bottle1 is a blend of premium materials, precise craftsmanship, and advanced technology. Glass is the primary material, shaped by molding and enhanced with finishes like printing or coating. The spray mechanism's quality and strict quality control are crucial for the final product.

As a manufacturer with over a decade of experience, I've seen brands get lost in the sea of options. A perfume bottle isn't just a container; it's the first physical interaction a customer has with your scent. It has to protect the delicate formula, feel substantial in the hand, and look stunning on a vanity. The process is a delicate dance between art and engineering. Let's break down what truly matters in creating a bottle that does justice to your fragrance.

What Are Perfume Bottles Actually Made Of?

You're worried about choosing the right material for your bottle. This single choice impacts the look, the cost, the safety of your perfume, and even your brand's sustainability story.

Glass is the undisputed king, making up over 95% of perfume bottles. Plastic is mainly for travel sizes or caps, while metal adds a premium touch to caps and components. Each material has specific types and best uses.

The material is the foundation of your bottle. In my factory, we handle these three main materials every day, each for a different purpose. For a new luxury brand, I almost always recommend a high-quality glass like super flint. Its clarity is unmatched and it’s chemically inert, meaning it won't react with the perfume. For a travel-size line, PETG plastic is a great choice because it's light and shatterproof. Metal, especially zinc alloy2, is our go-to for creating heavy, luxurious caps that give a satisfying "click" when closed. The choice defines the final product's character.

Material Quick Comparison

| Material | Common Types | Best For | Key Trade-Offs |

|---|---|---|---|

| Glass | Super Flint, Colored Glass | Main bottle body | Premium feel but heavy and fragile. |

| Plastic | PETG, PMMA (Acrylic) | Travel sizes, caps | Lightweight and cheap but can feel less luxurious. |

| Metal | Zinc Alloy, Aluminum | Caps, decorative parts | High-end feel and durable but more expensive. |

How Are These Intricate Designs Created?

You have a stunning design idea, but it's useless without the right manufacturing process. A misunderstanding of the craft leads to poor quality, blown budgets, and production delays for your brand.

Intricate designs are made through two key stages. First, forming the shape, usually by machine-blowing3 glass. Second, surface finishing4, where techniques like spraying, screen printing, or frosting are applied to create the final look and feel.

This is where art meets mass production. I remember a client who wanted a bottle with a very sharp, geometric shape. The initial machine-blowing3 trials resulted in slightly rounded edges. We had to adjust the mold design and cooling process multiple times to get it right. It's a game of micrometers. After the bottle is formed, the magic happens in the finishing department. We can spray on a gradient color, add a matte finish that feels soft to the touch, or hot-stamp a metallic logo that catches the light perfectly. Each step adds a layer of complexity and cost, but it's these details that make a bottle stand out.

Key Manufacturing Processes

- Bottle Shaping:

- Machine Blowing: The most common method. It's fast, consistent, and can create relatively complex shapes for mass production.

- Molding: Glass is pressed into a mold. It's efficient for simple shapes like cylinders or squares.

- Surface Finishing:

- Spraying: Applying color, from simple solids to complex gradients.

- Screen Printing / Hot Stamping: Used to print logos and text directly onto the glass. Hot stamping adds a metallic foil finish.

- Frosting: Creates a matte, non-glossy texture on the glass surface.

What's the Technology Behind a Flawless Spray?

A customer's final judgment of your perfume comes down to the spray. If it leaks, clogs, or sputters, the entire luxury experience is ruined, leading to returns and bad reviews.

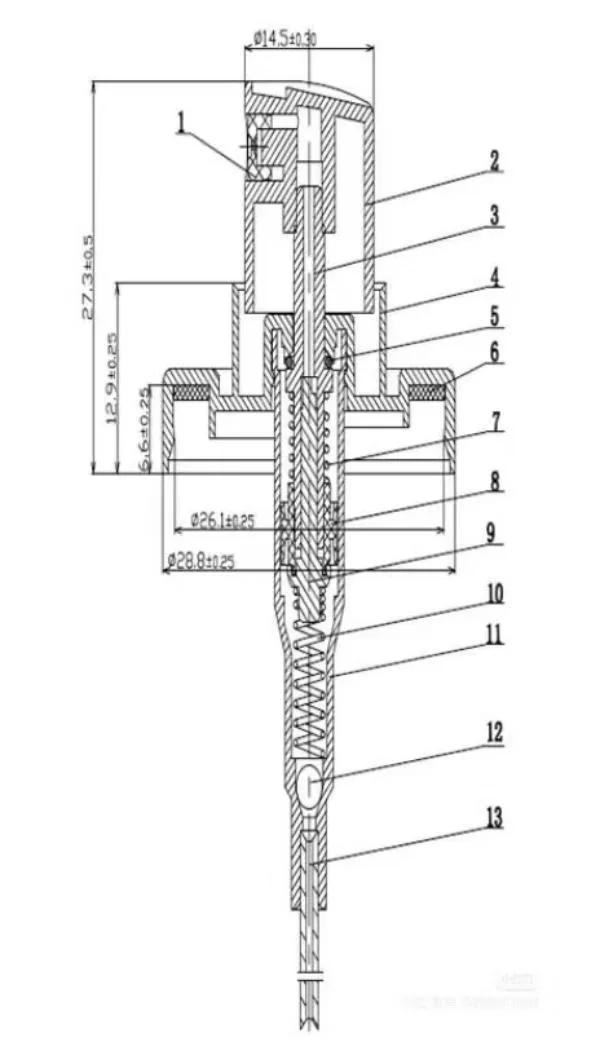

The secret is in the pump and sealing technology. High-precision molds create the components, automated lines assemble them perfectly, and advanced sealing materials prevent any leaks or evaporation. The entire system must be compatible with the alcohol-based fragrance.

The pump, or atomizer, is the soul of the bottle. We treat it like a precision instrument. The tiny parts—the spring, the gasket, the dip tube—must work together perfectly thousands of times. A huge part of our R&D is focused on this. We run tests to ensure the spray pattern is a fine, even mist, not a squirt. We perform leakage test5s under negative pressure to simulate air travel. And most importantly, we conduct long-term compatibility test6s, soaking the gaskets in the client's actual perfume for months to ensure they don't swell or degrade. A cheap pump is one of the easiest ways to destroy a premium product's reputation.

Core Technologies to Know

- Precision Molds: The foundation for high-quality glass bottles and all plastic/metal components.

- Automated Assembly: High-speed, robotic lines for assembling pumps ensure every unit is consistent and clean.

- Sealing Technology: The design of the valve and the choice of gasket material are critical to prevent leaks and evaporation.

- Automated Inspection (AOI): Cameras and sensors automatically check for defects in bottles, printing, and pump function online.

How Do You Ensure Every Single Bottle Is Perfect?

You worry that defects will slip through and reach your customers. A single flawed bottle can cause a social media complaint, damage your brand's reputation for quality, and be very costly.

Perfection is achieved through strict, multi-stage Quality Control (QC). This includes inspecting raw materials, monitoring the production process, and conducting extensive final tests on the finished bottle for appearance, dimensions, and performance, especially sealing and spray function.

Quality control in our world is obsessive. It's not just about looking at the final product. It starts the moment raw materials arrive. Our process is broken into three main stages. First, IQC (Incoming Quality Control) checks raw glass and metal. Then, IPQC (In-Process Quality Control) happens on the production line, where we check things like coating thickness and printing alignment every hour. Finally, FQC (Final Quality Control) is where we perform a battery of tests on the finished product. We test everything from the torque needed to open the cap to the spray volume per pump. This rigorous process is the only way to guarantee that millions of bottles meet the exact same high standard.

Key QC Checkpoints

- Appearance: Checking for scratches, bubbles in the glass, and color consistency.

- Dimensions: Ensuring height, diameter, and neck size match the technical drawings exactly.

- Performance Tests:

- Leakage Test: Using a vacuum chamber to ensure the bottle is perfectly sealed.

- Pump Function Test: Checking spray pattern, dosage, and durability.

- Adhesion Test: Making sure coatings and prints don't scratch off easily.

- Compatibility Test: Long-term testing with the actual fragrance to ensure no chemical reactions.

What Really Drives the Cost of a Perfume Bottle?

You need to manage your budget, but the costs seem unpredictable. Hidden expenses in molds, materials, and processing can quickly derail your project and shrink your profit margins.

The main costs are materials (30-60%) and processing (20-50%). Key drivers include material grade (e.g., super flint glass is pricier), design complexity, surface treatments (e.g., metallic coating is expensive), order quantity, and the required quality standard.

I always tell my clients to think of cost in three parts: molds, materials, and manufacturing. The mold is a one-time investment, but a complex bottle shape requires a more expensive mold. Material cost varies hugely. A bottle made from crystal-clear super flint glass with a heavy zinc alloy2 cap will cost much more than one from standard glass with a plastic cap. Finally, every manufacturing step adds cost. A simple, clear bottle is cheapest. If you add color spraying, that's one cost. Add a gold hot-stamped logo, that's another. The more complex the design, the higher the price, and a lower order quantity means each bottle has to absorb more of the setup and mold costs.

Major Cost Factors

| Cost Component | Key Influencers |

|---|---|

| Material Cost | Glass quality, type of metal/plastic, coatings. |

| Processing Cost | Bottle complexity, number of finishing steps (e.g., spray + print). |

| Mold Cost | A significant one-time cost, higher for complex shapes. |

| Order Quantity | Larger orders reduce the per-unit cost significantly. |

How Should You Manage Perfume Bottle Sourcing?

Sourcing seems overwhelming. You need to find a reliable supplier who can deliver high quality on time and on budget, but it's hard to know who to trust or what to ask for.

Start by creating a detailed technical specification sheet. Then, carefully evaluate suppliers based on their core capabilities, quality systems, and experience. Always manage the sampling and approval process rigorously before placing a bulk order.

My best advice for any brand, big or small, is to do your homework before you even contact a supplier. Create a document that specifies everything: the exact material, the Pantone color, the dimensions with tolerances, the required spray volume, and the tests you want it to pass. When you approach a manufacturer with this level of detail, you immediately signal that you are a serious partner. Then, vet them. Ask for their quality certifications. See samples of their work. Most importantly, run a full compatibility test with your fragrance on their samples before you sign anything. A good partner will work with you through this process, not rush you.

A Simple Sourcing Checklist

- Define Your Specs: Create a detailed technical document for your bottle.

- Vet Suppliers: Check their certifications (ISO 9001), equipment, and past work.

- Manage Sampling: Approve engineering samples and pre-production samples.

- Test Everything: Conduct your own tests for compatibility, leakage, and function.

- Sign a Clear Contract: Define quality standards, delivery terms, and intellectual property rights.

Conclusion

A successful perfume bottle perfectly balances art, science, and business. Focusing on the right material, craftsmanship, quality control, and sourcing process is key to creating an iconic product.

Explore the elements that make a perfume bottle luxurious and appealing to consumers. ↩

Learn about the advantages of using zinc alloy for creating premium bottle caps. ↩

Learn about the machine-blowing process and its role in creating glass bottles. ↩

Explore various surface finishing techniques that enhance the look and feel of bottles. ↩

Understand the importance of leakage tests in ensuring the reliability of perfume bottles. ↩

Learn how compatibility tests ensure that materials do not react with fragrances. ↩