You see glass bottles everywhere, but their composition and types are a mystery. Choosing the wrong one can impact your product's integrity, making your packaging decision a costly gamble.

Glass bottles are made from four main ingredients: silica sand, soda ash, limestone, and recycled glass (cullet). Common types include Boston rounds, wine and beer bottles, and various jar shapes, each designed for specific products and protective needs.

As someone who oversees the production of millions of glass containers for global export, I know these details are more than just trivia. They are the foundation of product safety, shelf life, and brand identity. Getting the right mix of materials and the perfect shape is crucial for success in any market. Let's start with the basics: the raw ingredients that turn simple sand into a durable, premium container.

What are the core ingredients of a glass bottle?

You probably know sand is in glass, but the other ingredients are a mystery. Without the right recipe, a bottle can be weak, unstable, or even unsafe for your product.

A glass bottle's core ingredients are silica sand (the main structure), soda ash (to lower melting temperature), limestone (for durability), and cullet (recycled glass), which boosts efficiency and sustainability.

The creation of commercial glass is a precise science relying on four essential components that we mix in a process called "batching." Each one has a critical job.

1. Silica Sand

This is the main glass former, making up about 60-75% of the mixture. The purity of the sand is vital, as it directly impacts the clarity and quality of the final bottle.

2. Soda Ash

Silica sand has an incredibly high melting point. We add soda ash to act as a flux, which lowers the melting temperature to a more manageable 1500°C. This saves a huge amount of energy.

3. Limestone

Without a stabilizer, the glass would be soluble in water. Limestone adds chemical durability, ensuring the container is strong, stable, and won't react with the contents.

4. Cullet (Recycled Glass)

This is our efficiency booster. Using crushed, recycled glass melts faster than raw materials, significantly reducing energy consumption and CO2 emissions, making it a key part of sustainable manufacturing.

How are glass bottles actually made?

Turning sand into a bottle seems like alchemy. This complex process can be confusing, making it hard to understand the difference between narrow-neck and wide-mouth container manufacturing.

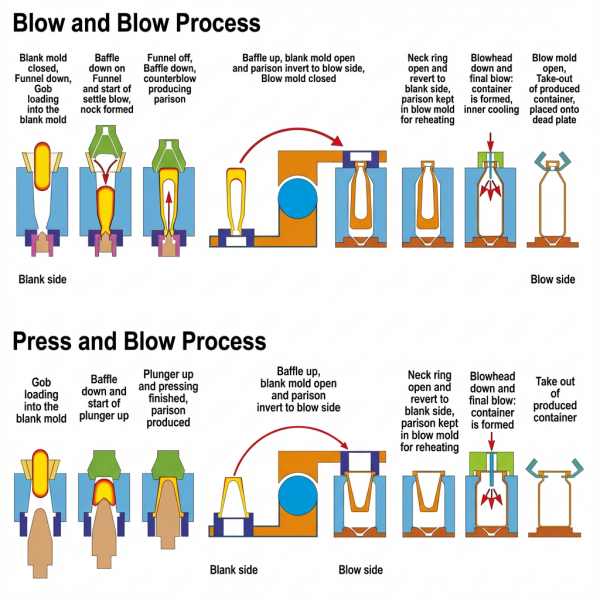

Molten glass is formed using two main methods: the Blow-and-Blow process for narrow-mouth bottles (like beer) and the Press-and-Blow process for wide-mouth jars. After forming, bottles are annealed (slowly cooled) for strength.

Once the raw materials are melted, we form the molten glass into containers using one of two primary methods, depending on the container's design. The choice is critical for achieving the right wall thickness and overall quality.

| Feature | Blow-and-Blow Process | Press-and-Blow Process |

|---|---|---|

| Best For | Narrow-mouth containers (e.g., beer, wine bottles) | Wide-mouth containers (e.g., food jars) |

| Process | Air pressure forms the initial shape and final bottle. | A plunger presses the initial shape, then air forms it. |

| Wall Thickness | Less uniform wall distribution. | More uniform wall distribution. |

After a bottle is formed, it's not ready yet. It must go through an annealing lehr, which is a long oven that cools the container in a slow, controlled way. This process removes internal stresses that would otherwise cause the glass to crack or shatter easily. Finally, every bottle undergoes rigorous automated and manual inspections to ensure it meets our quality standards before it's ready for shipping.

What are the most common types of glass bottles?

You know bottles come in different shapes and colors, but you're not sure which is right for your product. Choosing based on looks alone can lead to spoilage or a mismatched brand identity.

The most common bottle types are defined by color (Amber for UV protection, Flint for clarity) and shape (Boston Round for versatility, specific Wine/Beer shapes, and Jars like Hex and Paragon for food).

The type of glass container you choose is vital for both product protection and market appeal. We can categorize them in two main ways: by color and by shape.

Types by Color

The color of a bottle isn't just for show; it's a functional feature for protection.

- Amber: Offers the best UV light protection, making it essential for beer, pharmaceuticals, and essential oils.

- Flint (Clear): Provides maximum visibility to showcase the product. It offers no UV protection.

- Green: Gives moderate UV protection and is traditionally used for wine.

- Blue: Chosen mainly for aesthetics for products like high-end water and cosmetics. It offers minimal UV protection.

Types by Shape

The shape is designed for a specific function and application.

- Boston Round: A classic with rounded shoulders, used for pharmaceuticals, chemicals, and personal care.

- Wine Bottles: Standardized shapes like Bordeaux (high shoulder) and Burgundy (sloped shoulder).

- Hex Jars: Six-sided jars that are great for labeling jams and honey.

- Paragon Jars: Tall, slender jars perfect for pickles and olives.

Conclusion

Understanding glass, from its four core ingredients to its various forms, is key to choosing the right packaging. This choice protects your product, defines your brand, and ensures market success.