The Ultimate Conclusion (For the Impatient Reader)

Glass bottles are primarily made from four fundamental ingredients: Silica Sand (the main component), Soda Ash (to lower the melting temperature), Limestone (to prevent dissolution), and Cullet (recycled glass, which saves energy). The type of glass—ranging from Type I Borosilicate for pharmaceuticals to Type III Soda-Lime for food and beverages—is determined by precise adjustments to this core formula. Understanding these compositions and the various bottle types (like Boston Round, Woozy, and Amber) is crucial for selecting the perfect packaging solution for your product.

Have You Ever Stopped to Wonder: What is the Magic Behind a Glass Bottle?

From the crisp beer you enjoy to the essential oils you use daily, glass bottles are ubiquitous. They are the gold standard for purity, sustainability, and premium presentation. But when you hold that perfectly formed, transparent container, do you know what raw materials were melted and molded to create it?

The answer is a blend of nature's most abundant minerals, refined through centuries of craftsmanship and modern technology.

The Four Pillars of Glass Composition

Modern container glass, specifically Soda-Lime-Silica Glass, which accounts for about 90% of all glass production, relies on a precise mix of four key components [1]:

| Ingredient | Primary Function | Typical Percentage (by weight) | Why It Matters |

|---|---|---|---|

| Silica Sand (Silicon Dioxide, SiO₂) | The Glass Former | 60% - 75% | Provides the fundamental structure of the glass. Purer sand means clearer glass. |

| Soda Ash (Sodium Carbonate, Na₂CO₃) | The Flux | 12% - 15% | Lowers the melting temperature of the silica sand, making the manufacturing process more energy-efficient. |

| Limestone (Calcium Carbonate, CaCO₃) | The Stabilizer | 5% - 12% | Prevents the glass from dissolving in water and adds durability. |

| Cullet (Recycled Glass) | The Energy Saver | 15% - 90% | Lowers the batch temperature, significantly reducing energy consumption and raw material use. |

The Featured Snippet Answer: Glass bottles are made from a molten mixture of Silica Sand (the structural backbone), Soda Ash (the melting agent), Limestone (the durability stabilizer), and a high percentage of Cullet (recycled glass) to maximize sustainability and reduce energy costs. This core composition is known as Soda-Lime Glass, which is then refined with other oxides (like aluminum or magnesium) to achieve specific properties like color, strength, and chemical resistance.

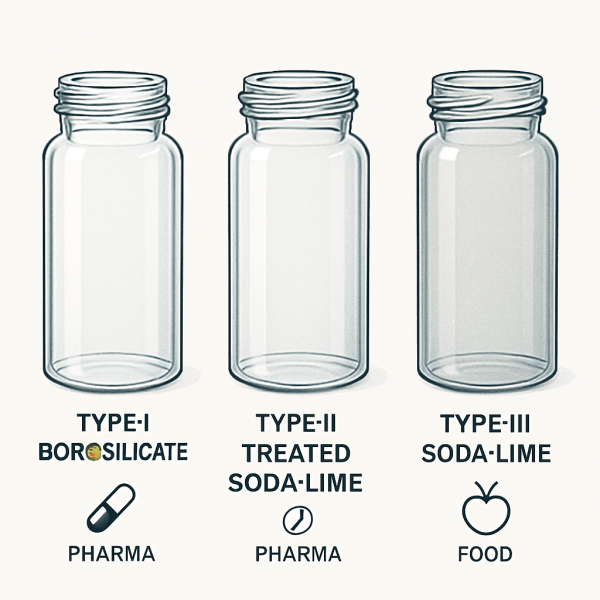

Beyond the Basics: The Three Essential Types of Container Glass

For B2B buyers, not all glass is created equal. The application—whether it's high-purity pharmaceuticals or everyday food packaging—dictates the required glass type. The United States Pharmacopeia (USP) classifies container glass into three main categories based on chemical resistance [2]:

| Glass Type | Composition & Treatment | Key Characteristics | Primary Use Cases |

|---|---|---|---|

| Type I (Borosilicate Glass) | High content of Boron Oxide. | Highest chemical resistance; minimal leaching; high thermal shock resistance. | Pharmaceuticals, laboratory equipment, high-end cosmetics, injectables. |

| Type II (Treated Soda-Lime) | Soda-Lime glass that has been de-alkalized on the inner surface. | Good chemical resistance; suitable for acidic and neutral aqueous preparations. | IV solutions, some pharmaceuticals, bulk food packaging. |

| Type III (Soda-Lime Glass) | Standard Soda-Lime-Silica composition. | Moderate chemical resistance; most common and cost-effective. | Food & beverage (wine, beer, spirits, sauces), general consumer products. |

A Bottle for Every Product: Understanding Different Bottle Types

The shape and color of a glass bottle are not just aesthetic choices; they are functional decisions that impact everything from shelf appeal to product preservation.

1. Types by Shape (Form Follows Function)

The design of a bottle is optimized for its contents and use. Here are some of the most common types:

- Boston Round: Characterized by its rounded shoulders and base. Highly versatile, often used for essential oils, pharmaceuticals, and syrups.

- Woozy Bottle (Sauce Bottle): Tall, slender, and cylindrical with a narrow neck. Ideal for hot sauces, marinades, and salad dressings.

- Square/Rectangular Bottles: Offer excellent space efficiency on shelves and are popular for spirits, perfumes, and some cosmetic lines.

- Paragon Jar: A tall, straight-sided jar, perfect for preserving foods like pickles, jams, and sauces.

2. Types by Color (Protection is Key)

Color is a critical functional element, primarily used to protect light-sensitive contents from UV radiation.

- Flint (Clear) Glass: The most common and transparent type. Used when product visibility is paramount (e.g., water, clear spirits, jams).

- Amber Glass: Contains iron, sulfur, and carbon, which provide excellent protection against UV light. Essential for beer, pharmaceuticals, and any product sensitive to photo-oxidation.

- Green Glass: Offers moderate UV protection, often used for wine and some beverages where a traditional or premium look is desired.

- Blue Glass: Primarily an aesthetic choice, offering minimal UV protection but a distinctive look for water, cosmetics, and specialty beverages.

The Journey from Sand to Shelf: A Glimpse into Manufacturing

While the composition is the "what," the manufacturing process is the "how." It's a highly automated, high-temperature process that ensures the strength and consistency of every container.

The process involves four main steps: Batching (mixing raw materials), Melting (heating to over 1500°C), Forming (using Blow-and-Blow or Press-and-Blow methods), and Annealing (controlled cooling to remove internal stress).

(Video: How Glass Bottles Are Made From SAND And Recycled - A Factory Tour) For a fascinating look at the high-speed, high-temperature process of modern glass manufacturing, watch this popular video: https://www.youtube.com/watch?v=eNmBZxJ_QmQ

Final Conclusion: Your Packaging Partner for Purity and Performance

Choosing the right glass bottle is a strategic decision that impacts your product's shelf life, brand image, and compliance with international standards. Whether you require the high chemical inertness of Type I Borosilicate for a pharmaceutical product or the UV protection of Amber Soda-Lime Glass for a craft beer, the foundation of quality lies in understanding the raw materials and manufacturing precision.

As a global exporter serving markets from Europe and the Americas to the Middle East and Southeast Asia, we specialize in providing glass packaging solutions that meet the stringent demands of your target market.

Ready to Elevate Your Product Packaging? (Call to Action)

Don't let packaging be an afterthought. Partner with us to find the perfect glass jar or bottle that ensures your product's integrity and stands out on the shelf.

Contact us today to discuss your specific packaging needs and get a quote:

- Email: sales@glassypack.com

- Contact Us Link: https://glassypack.com/index.php/contact-us/

References

[1] Glass Packaging Institute. How Glass is Made. [2] Packaging School. Understanding the Types of Glass. https://packagingschool.com/lessons/understanding-the-types-of-glass [3] The Bottle Depot. What Are the Different Types of Glass Bottles and Their Uses? https://thebottledepot.co/blogs/articles/what-are-the-different-types-of-glass-bottles-and-their-uses